FAMILY HOME

We designed the house from a 1917 Sears Kit House catalog. It is two story and 3100 square feet. The garage is 26 feet square and on the back side of the house. The front sitting porch is 14 feet wide by 26 feet long. It took most of our spare time the year before we retired to finalize the plans. We tried to stay with the old look all the way. Note the triangular brackets on the roof overhangs. They were a bit superstitious back then and for some reason did a lot of things in threes - like three types of siding, windows in sets of three and three main bays in the house interior.

FAMILY HOME

This doesn’t show it very well, but the front porch roof had to be designed for wind lift as well as snow load. The three pillars in front are cast in approx 1-1/2 yards each solid concrete. The posts are 6 inch by 6 inch and were sawed up the center and I cut a dado up the center of each post. They were then glued back together. There are a total of eight posts and each has a 1/2 inch steel rod running up the dado. The rods were bent at the bottom and set into the concrete. The tops of the rods run through the beam on top and have a 1/4-inch thick by 3-inch washer with a double nut. The reason for this is we are on the top of a hill and the wind gusts can get up to 60 mph in the winter. The house was constructed with Structurally Engineered Panels (SIP) and has an insulation rating of R40.

SHOP BUILDING

30’ x 40’ single story shop pole building .

EUROPEAN WORK BENCH

The European style work bench was constructed with a tool tray. It measures 76 inches long by 32 inches wide and 30 inches tall. The top and leg assemblies are made from 4x4s cut to 3x3s. The top is glued together and has six 3/8-inch threaded rods running through the 3x3s. The draw bolts are inset into each side and left open so they could be tightened in the future if needed. I built in six drawers on the tool tray side and added three woodworking vises. I also built in a series of 3/4-inch square holes for bench stops.

EUROPEAN STYLE WORK BENCH

I installed an 8-inch leg vise on the working side of this bench. I had a big bench screw from my old bench and it was just the right size to use. The bottom of the vise jaw has a double steel strap and pins to adjust the vise for wider openings (up to 16 inches). I also made a sliding work support with an aluminum pin to support long boards. The leg vise jaws have 1/4-inch leather pads glued to them to protect my work from vise marks. Normally, this type of work bench would be made from maple, but my old bench, made from 2x4s lasted for more than 20 years.

TIN SIGNS

I like to collect tin signs from our travels and mount them on the wall.

TEMPLATE STORAGE

I hang patterns and templates for many of my past projects high on the wall out of the way. They can be used again in the future if needed.

WALL HANGING TOOL BOX

I keep most of the tools I use a lot in this box. Tools are mounted both inside and outside of the doors. It was made from one 4’x8’ sheet of 3/4” plywood. I was re-arranging my shop when my daughter took the photographs. I was hoping to get things put away but she thought it added more character.

TOOL CADDY

I built this to hold tools I use on every project. It has a 3/4” plywood top with a metal cup for small items. It sits on a 2” dowel post mounted to an office chair dolly at the bottom. I can move it to any place in the shop where I am working.

WALL STORAGE

The items stored on this wall in my shop include levels, hand saws and straight edges. The shelf below holds tool sharpening equipment.

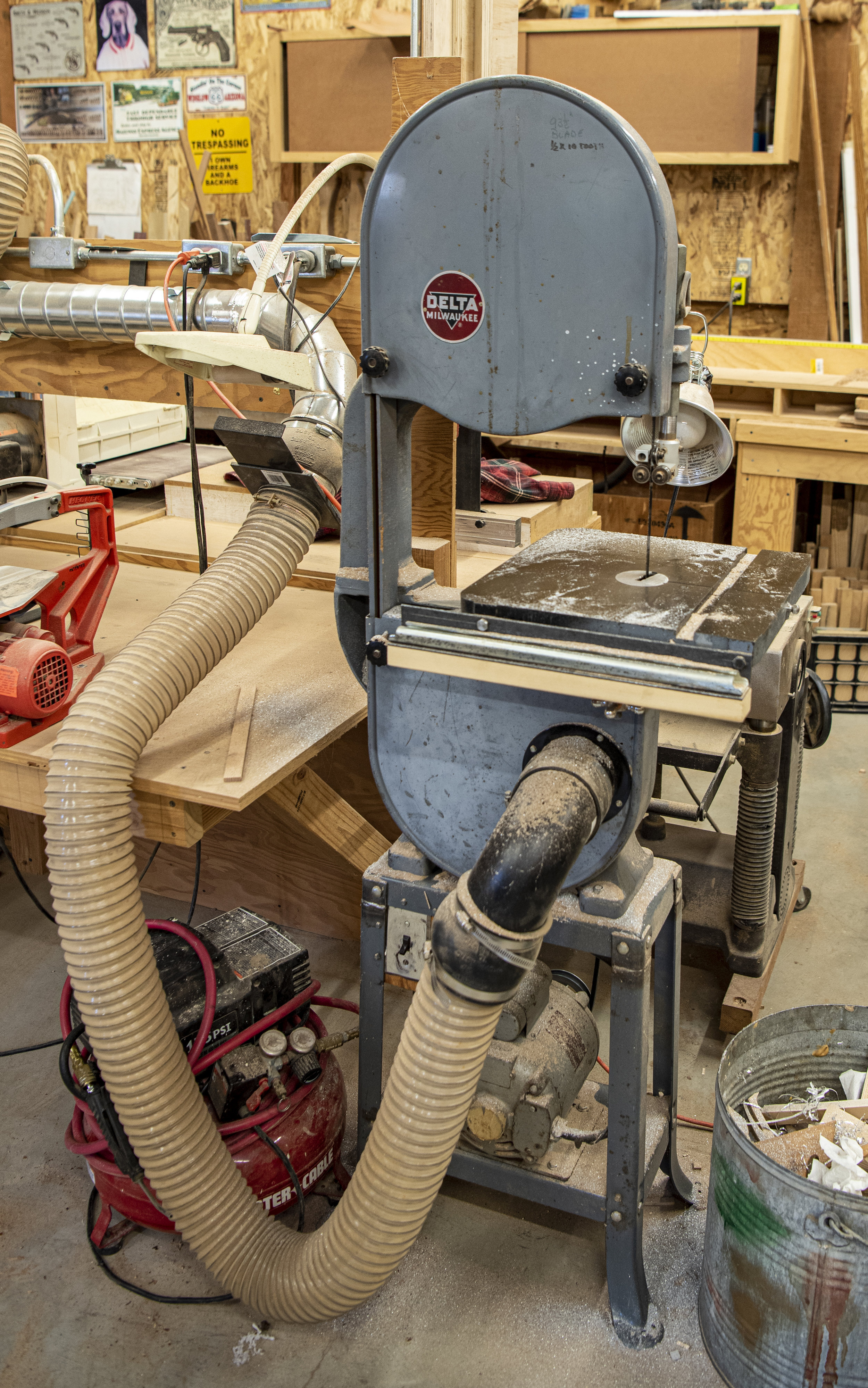

BAND SAW

My grandfather purchased this 14” bandsaw as a gift for my father when he got out of the Navy at the end of WWII. You don’t see a Delta-Milwaukee plate on equipment any more.

ANTIQUE TOOL COLLECTION

This is a small collection of antique tools. The hewing axe and adz belonged to my grandfather

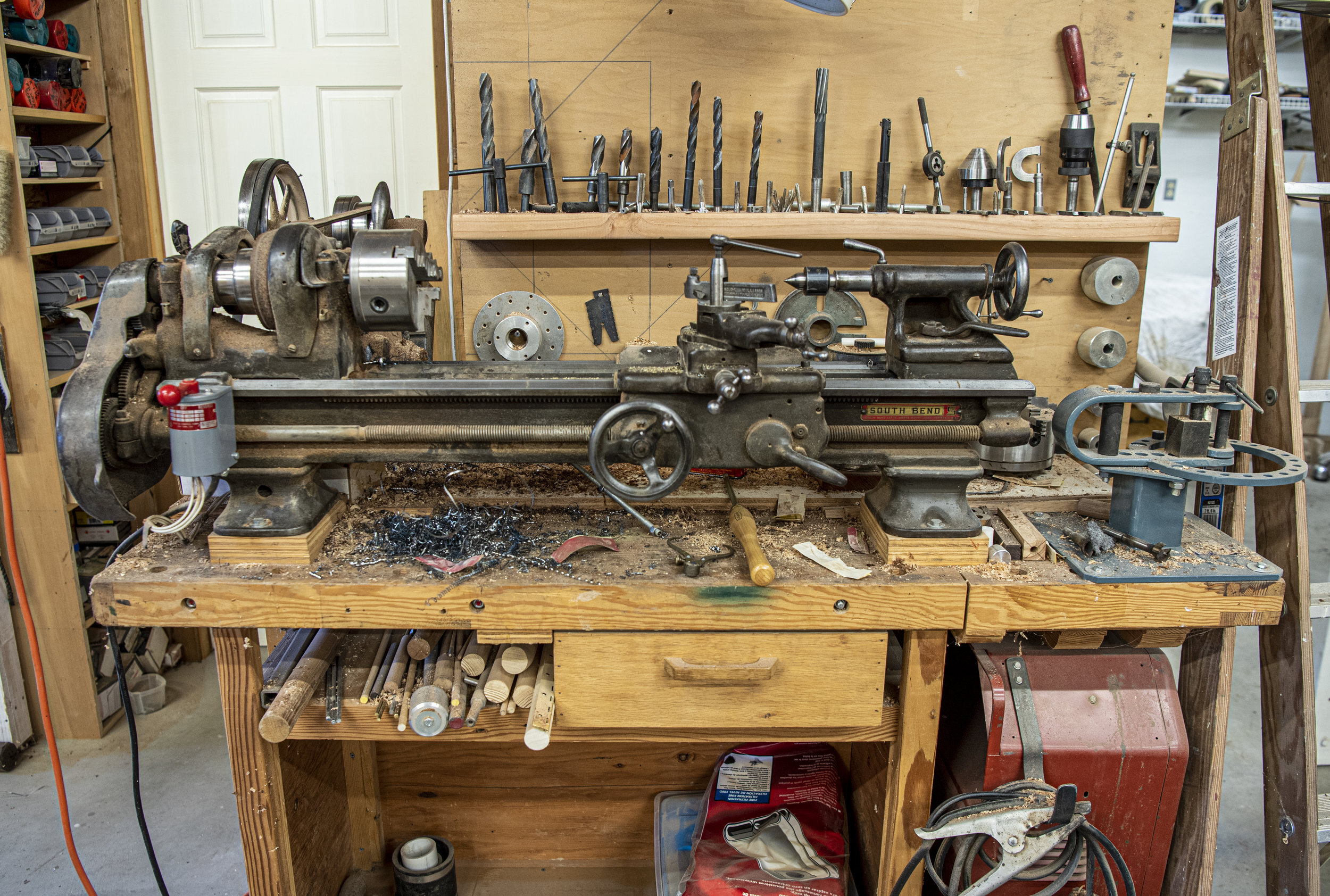

SOUTHBEND LATHE

This is a 9” South Bend Metal turning lathe. It was built in 1941 and does not have quick change gears for the cut feed. It is driven with a 1-1/4” wide leather belt. It has a 6” 3-jaw chuck and an 8” 4-jaw chuck along with a face plate. I have most of the standard tooling. I use it for metal, plastic, and wood turning.

DUPLICATING FIXTURE

This small duplicating fixture is built from wood. Above to the right is a couple of templates and below them are some practice engravings. The large hole in the front link is for a small router. On the link at the bottom is the stylus to follow the pattern. Note the white knob on the stylus. It is changeable for others that match the shape of the cutter that is used.

SHOP INTERIOR

SHOP INTERIOR AND MATERIAL STORAGE